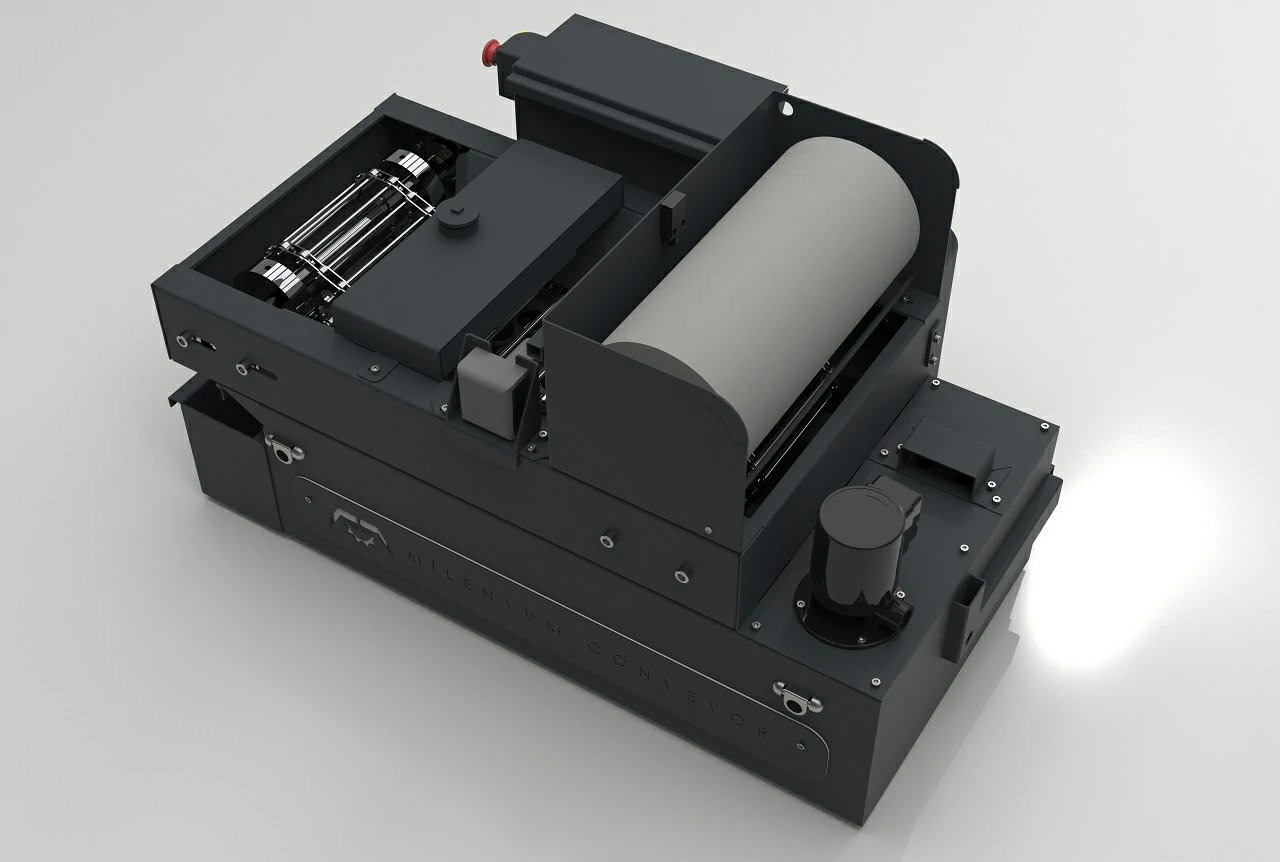

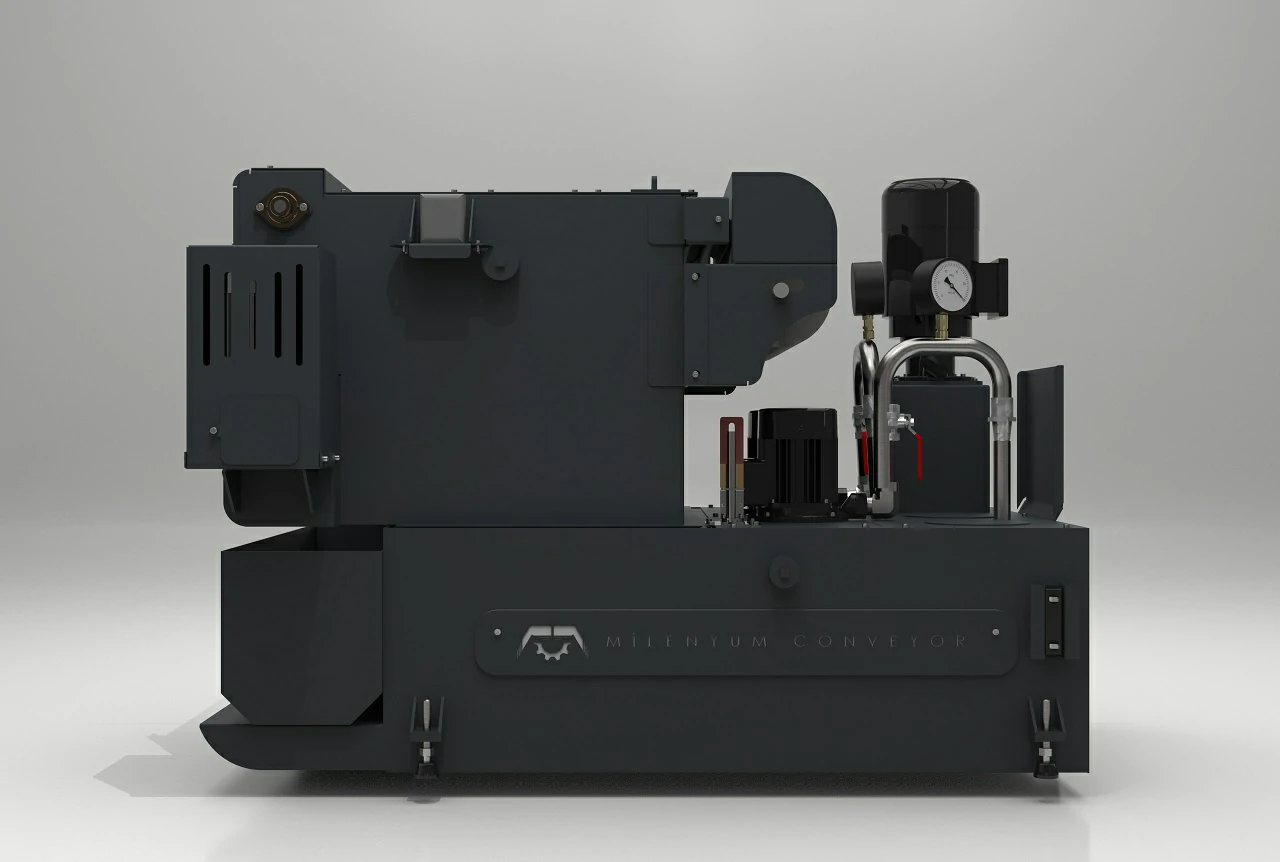

MILCLEAN FILTRATION SERIES

The Milenyum Milclean filtration series is designed to overcome the most challenging filtration tasks. Thanks to its unique filtration system, it provides seamless operation with minimal maintenance. Milclean ensures superior filtration performance by separating chips and particles from the cutting oil inside the tank. It is specifically designed to separate small dust, chip fragments, and fine particles generated during the processing of metal materials.

It achieves high efficiency in the filtration of chips from CNC machining centers, CNC (Broach) Pulling Machines, Grinding Machines, Honing Machines, and CNC milling machines. The chips purified from the cutting fluid, carried on the moving paper filter, are discharged through a powerful motor hidden under the protective plate.

Why Milclean Series ?

Milenyum Milclean filtration systems eliminate the issues of paper filter tearing and chip mixing with the cooling fluid caused by small-sized chips in other types of separators, thanks to their innovative design.

Show 3D- Paper Filter Savings

- High Filtration Power

- Serial Operation

- Lower costs

- Space Saving

- Filtering Between 25 - 50 μm

- Customized Capacity

- High Pressure Pump

- Recirculation Pump

- Auto Switch

- Magnetic Unit

- Custom design

- Integrated Coolant Tank

- Fully Automatic Operation

- Waste Oil Separator

- Cast iron

- Steel

- Iron Material

- Aluminum

- Cobalt Fine Chip

- Broken Chip

- Small Chips

- Powder Chips

- Other Micron Size Chips

- Coolant Tanks

- High Temperature Resistance

- Oil Skimmers

- High Pressure Pump

- Recirculation pump

- Full Automation

- Magnetic Unit

- Capacity: 50 - 1000 L/min

- Pump: 50 - 1000 L/min (Can Be Increased or Decreased Optionally)

- Engine Power: 0,18 - 0,37 kW

- Magnetic Drum: Ø 140 - 180 mm

- Electrical Connection: Panel, Switch, Socket, PLC

- Paper Filter: 25 - 50 μm

In the Milclean series, the dirty coolant, upon reaching the separator, is filtered through the use of the paper filter. As the pores of the dirty coolant filter become clogged, the liquid level rises, and a signal received from the automatic switch causes the dirty paper filter to advance forward, making way for a clean paper filter. The area containing the dirty coolant continues the filtration process with the new paper filter. Chips and particles do not enter the integrated coolant tank. Therefore, sharp, abrasive chips cannot reach and damage the machine's cooling components. Maintenance in the Milclean series is minimal, and aside from the electric motor, the parts that need protection are completely enclosed. The Milclean series, highly beneficial for machines requiring coolant, is available in various sizes and configurations according to customer preferences.