A chip breaker is a machine used in the metal processing industry to break and crush long and adhesive chips that arise during machining processes such as turning, milling, or drilling. These chips are typically generated by machining tools. Chip breakers facilitate the processing of these long chips by transforming them into smaller, more manageable pieces, thereby improving waste management. Additionally, they contribute to more effective collection of chips produced by machining tools.

Chip breakers may possess the following features:

Shredding Capability:Chip breakers are designed to break long and adhesive chips, making it easier to process and manage the chips by reducing them into smaller pieces.

Fast and Efficient Operation:The ability to quickly and efficiently break chips from machining tools optimizes production processes.

Integration Capability:Chip breakers can often be integrated with chip transport systems. This integration enhances the efficiency of the processes involving the collection and breaking of chips from machining tools.

Waste Reduction:Breaking long chips improves waste management by making them easier to handle. The resulting smaller chips are also more easily recyclable.

Rejecting Bar Ends:Some chip breakers have the capability to reject bar ends, enhancing operational efficiency.

Chip breakers are commonly used as part of chip management systems in metal processing facilities, automotive manufacturing plants, and other industrial environments.

- Design According to Product Diameter

- Automation

- Adjustable Speed

- Capacity Options

- Metal Processing Industry

- Automotive Industry

- Aviation Industry

- Energy sector

- Machinery Manufacturing

- Defense Industry

- Model DK 3

- Model DK 10

- Model DK 20

- Model DK 30

- Model DK 49

- Motor Power: 2.2, 7.5, 15, 37, 45 kW

- Steel and brass chip capacity: 100, 400-700, 800-1000, 2000-5000, 5000-8000 kg/h

- Aluminum Chip Capacity: 40, 150-250, 250-350, 700-1650, 1650-2650 kg/h

- Height:1150, 1200, 1915, 3060, 2980 mm

- Weight:150, 800, 1150, 4500, 6500 kg

- Space Requirements:1350x500, 1250x900, 1425x1000, 1740x1520, 2700x2200** mm

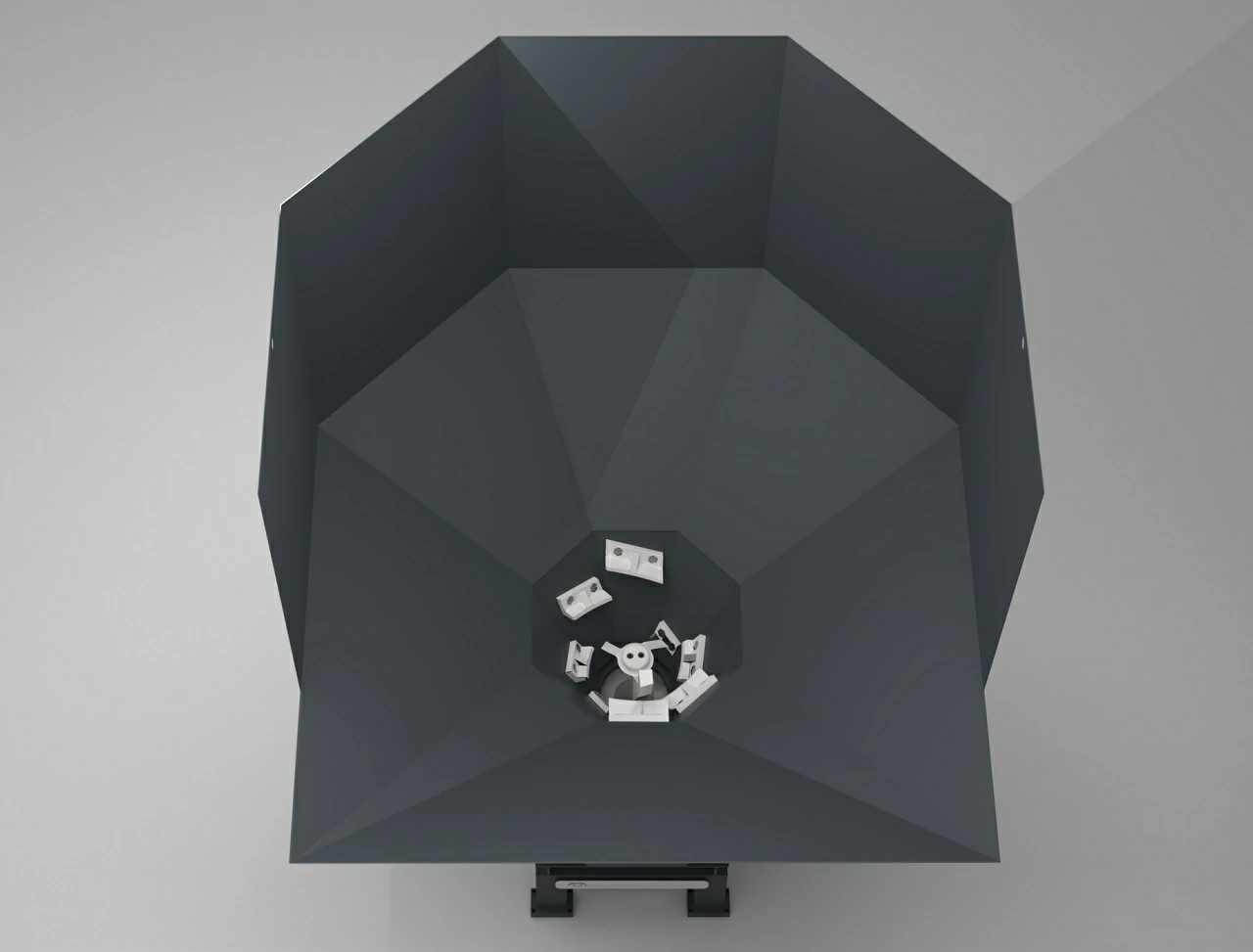

MILENYUM CONVEYOR CHIP BREAKER

- Automatic solid material discharge

- Interchangeability of cutters and intermediate parts minimizing part requirements

- Extended length teeth for shredding efficiency and grinding power

- Large-sized, high-torque electric motor drive

- Simple on-site sliding gears

- Large spindle

- Sealed, externally lubricated spindle bearings

- Adjustable spring tension

A rotary cutter high-speed impact crusher, perfect for the medium and fine grinding of metal chips and shavings.

Product size can be controlled by the choice of grid bar opening.